BaSPAT – The Story Behind The Product

Written by Matias Riihinen, Roni Åvist and Markus Siltakoski

At Oulu University of Applied Sciences, first year students created prototypes as a part of the Innovative Product Development course. These prototypes were presented at the Product Fair where our international guests and our teachers had a chance to see the huge potential our future engineers have.

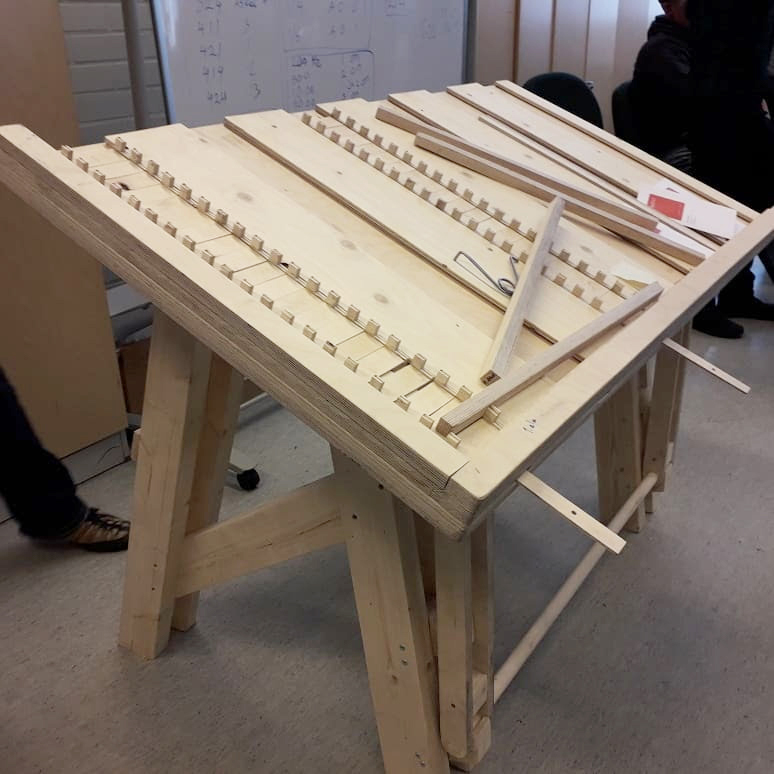

The idea to our project came from the father of one of the team members. He works in a company and wanted a solution for their problem. The problem is a slow and difficult production process of batten strip panels. Our job was to invent a method to produce these batten strip panels more easily. Our solution was to design a modular assembly table.

This gave us a chance to see the whole process from drafting to production. Understanding this process is also important for future projects.

The fact that we were doing this project for a company increased our motivation to make the product functional and profitable for the company. In the first weeks we focused our efforts on making drafts and working 3D-models. With careful planning we tried to prevent future problems with the manufacturing of the prototype.

Best lessons come from mistakes

Our careful planning proved to be futile as in the manufacturing phase we revealed few problems with the design. Manufacturing tolerances were not adequately taken into account and our inability to use tools in the proper way did not help.

The biggest thing that we learned was that worker skill and manufacturing deviation in general play a bigger role in the final product quality than we originally anticipated. Another lesson was that we should rethink our material and production methods because the ones we used did not work in practice.

Product Fair

Difficulties with production did not rise hope for the success of the prototype in the Product Fair but it ended up been popular among the guests and teachers. The prototype was praised for its innovativeness, quality and the thought that had been put in it which showed on the final prototype. It ended up getting most votes from the guests.

This project was a success despite all the problems we faced. All this required lots of working hours and a strong team spirit which took many hits during the project. Through all this the team is now stronger than before the project and ready to face new challenges.

Btw, BaSPAT is an abbreviation of “Batten Strip Panel Assembly Table”.